7 articles-Critical points in precision injection molding

Precision injection molding will be affected by many related factors and environmental conditions, and the most basic are the four basic factors of plastic materials, injection molds, injection molding process and injection molding equipment.

In the early stage of designing plastic products, the engineering plastics should be selected according to their application environment with corresponding performance needs.

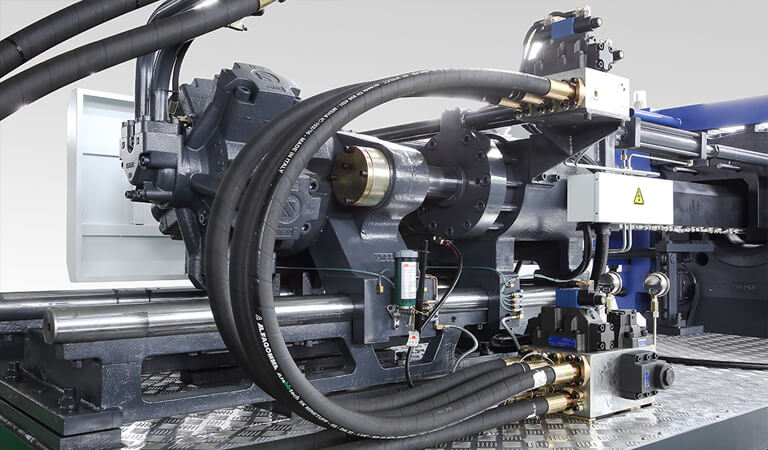

Secondly, the appropriate injection molding machine should be selected according to the selected plastic material, the dimensional accuracy of the finished product, the weight of the part, the quality requirements and the expected mold structure.

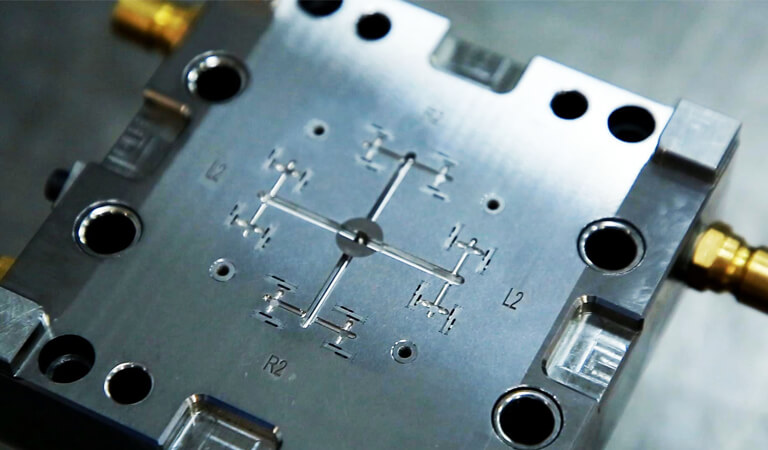

Among the factors that affect precision injection molding, the mold is the key to obtaining precision plastic products that meet quality requirements.

Design of molds

Whether the mold design is reasonable or not will directly affect the quality of plastic products.

Since the mold cavity size is derived from the required size of the plastic product plus the shrinkage rate of the material used, and the shrinkage rate is often a range of values recommended by the plastic manufacturer or engineering plastics manual, it is not only related to the mold gate form

gate location and distribution, but also related to the crystalline orientation of engineering plastics (anisotropy), the shape and size of the plastic product to the distance and location of the gate.

The main factors affecting the shrinkage of plastics include thermal shrinkage, phase change shrinkage, orientation shrinkage, compression shrinkage and elastic recovery, which are related to the molding conditions or operating conditions of precision injection molded products.

Therefore, the designer of the mold must have rich experience in design and injection molding, and must consider the relationship between these influencing factors and injection conditions and their apparent factors

such as injection pressure and cavity pressure and filling speed, injection melt temperature and mold temperature, mold structure and gate form and distribution, as well as gate cross-sectional area, product wall thickness

the content of reinforcing filler in plastic materials, the crystallinity and orientation of plastic materials, etc. The influence of factors such as

The influence of the above factors also varies depending on the plastic material, or other molding conditions such as temperature, humidity, continued crystallization, internal stress after molding, and variations in the injection molding machine.

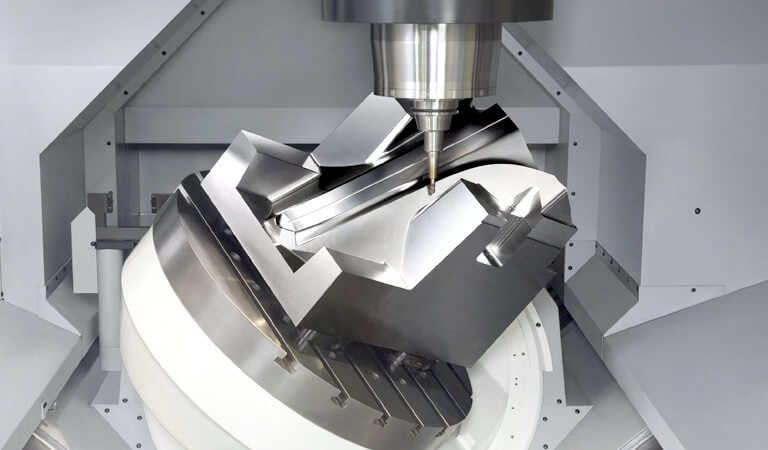

Since the injection molding process is to transform the plastic from solid (powder or pellet) to liquid (melt) and then to solid (product). From the pellet to the melt, and then from the melt to the product, there are temperature fields, stress fields, flow fields and density fields in between.

Under the joint action of these fields, different plastics (Thermosetting or thermoplastic, crystalline or non-crystalline, reinforced or non-reinforced, etc.) have different polymer structural forms and rheological properties.

All the factors affecting the above "field" will definitely affect the physical and mechanical properties, size, shape, precision and appearance quality of plastic products.

In this way, the intrinsic connection between process factors and polymer properties, structural forms and plastic products will be expressed through plastic products.

The analysis of these intrinsic links is important for the reasonable formulation of the injection molding process, the reasonable design and manufacture of molds according to the drawings, and even the reasonable selection of injection molding equipment.

Precision injection molding is different from ordinary injection molding in terms of injection pressure and injection rate. Precision injection molding often adopts high pressure or ultra-high pressure injection and high speed injection to obtain a smaller molding shrinkage.

The following points also need to be considered:

1、Adopting appropriate mold dimensional tolerances.

2、 Preventing the generation of molding shrinkage errors.

3、Preventing the occurrence of injection deformation.

4、Prevent the occurrence of demoulding deformation.

5、Minimize the error of mold manufacturing.

6、Preventing the error of mould precision.

7、Keep the mold accuracy.

Prevents molding shrinkage errors

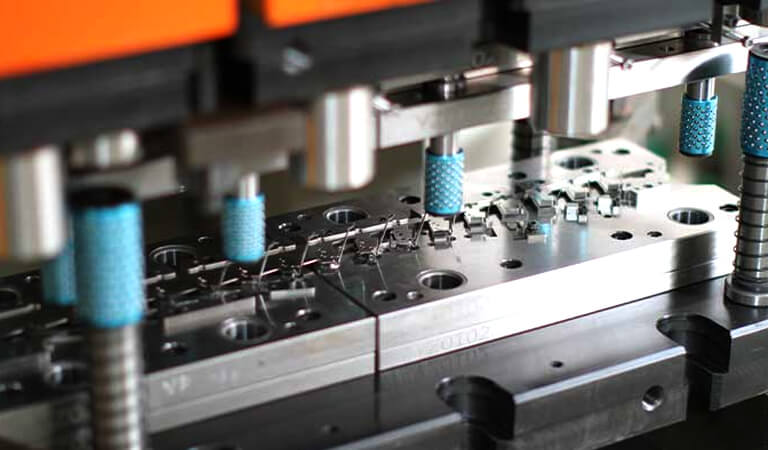

Since the shrinkage rate will change due to the injection pressure, for single-cavity molds, the cavity pressure within the cavities should be as consistent as possible.

As for multi-cavity molds, the cavity pressure between cavities should be very different. In the case of single-cavity multi-gate or multi-cavity multi-gate, it is necessary to inject with the same injection pressure so that the cavity pressure is consistent.

For this purpose, it must be ensured that the gate positions are equalized

In order to have a consistent pressure in the mold cavity, it is desirable to have a consistent pressure at the gate entrance.

The equalization of the pressure at the gate is related to the flow resistance in the runner.

Therefore, the flow path should be equalized before the gate pressure is equalized.

Since the melt temperature and mold temperature have an effect on the actual shrinkage rate, attention must be paid to the arrangement of the cavities when designing the precision injection mold cavities in order to facilitate the determination of the molding conditions.

This is because the molten plastic brings heat into the mold, and the temperature gradient distribution of the mold is generally around the cavity in a concentric circle shape centered on the main flow path.

Therefore, the design measures such as balanced flow path, cavity arrangement and concentric circle arrangement centered on the main flow path are necessary to reduce the shrinkage error between cavities, expand the allowable range of molding conditions and reduce the cost.

The cavity arrangement of precision injection molding tool should meet the requirements of balanced flow path and main flow path as the center of the two requirements, and must use the main flow path as the symmetry line of cavity arrangement

Thank you for watching and please click here to learn more about us now, thank you!

Website:gmolding.com

E-mail;kaiwin@grashine.com