2 Big Cases - Understanding Transparent Plastic Products

2 Big Cases - Understanding Transparent Plastic Products Due to the high light transmittance of transparent plastics, the surface quality of plastic products must

2 Big Cases - Understanding Transparent Plastic Products Due to the high light transmittance of transparent plastics, the surface quality of plastic products must

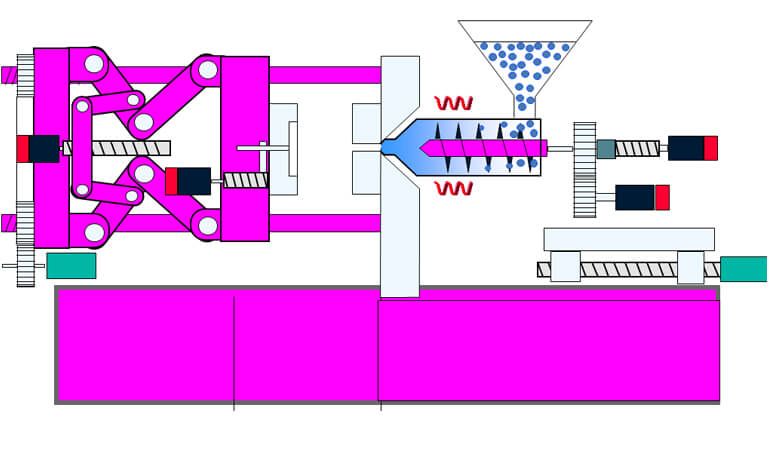

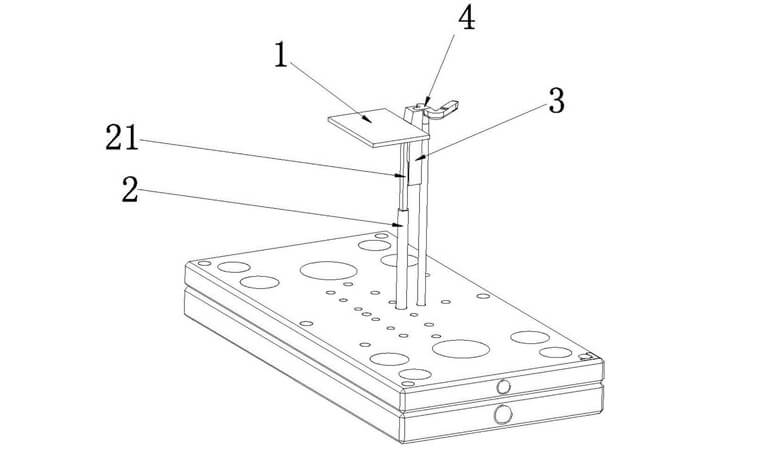

7 examples to tell you thoroughly what is an injection mold? Mold injection molding is a processing method used in mass production of some

9 Cases— Injection Mold Troubleshooting Injection mold is a tool for producing plastic products; it is also a tool for giving plastic products complete structure

7 articles-Critical points in precision injection molding Precision injection molding will be affected by many related factors and environmental conditions, and the most basic are

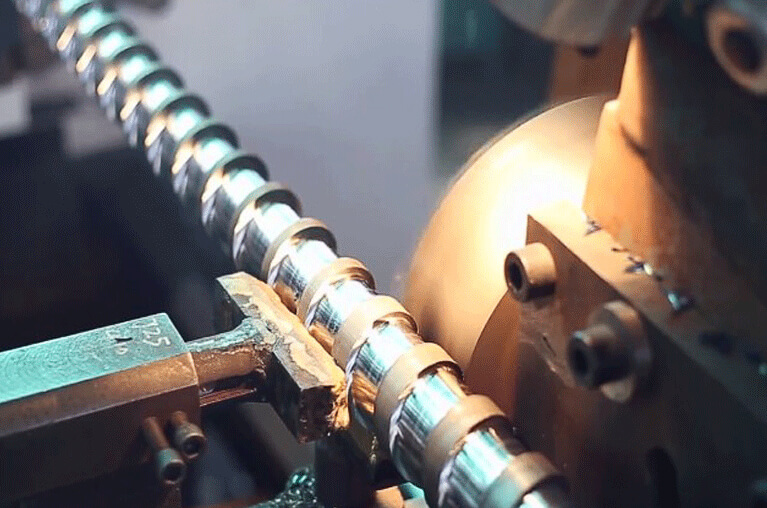

How to improve the working life of plastic machine screw? How to improve the working life of plastic machine screw barrel? The injection molding screw

2 practical tips to reduce deformation of aluminum There are many reasons for the deformation of aluminum parts, which are related to the material, shape

50 Tips for Reducing Energy Consumption in Injection Molding For an injection molding factory, the energy consumption occupied by the injection molding process accounts for

5 types of injection molding workshop safety regulations General rules for safe production in injection molding workshop. 1、When the equipment is in normal operation, it

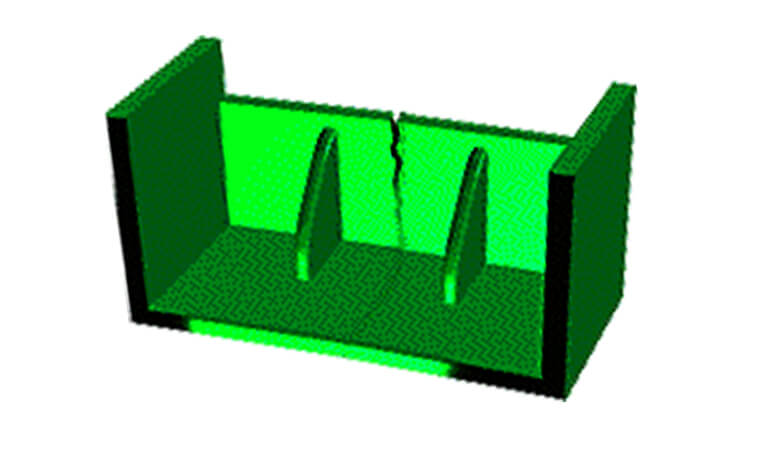

I、Terminology explanation Cracks are formed on the surface of the molded product and are called cracks. 1、The residual stress is too high. In mold design

Injection Molding 11 Big Elements Explained 11 Elements of Injection Molding The purpose of injection molding is to transform the raw materials of thermoplastics into

Causes of poor gate cutting - 3 major countermeasures l、What is a bad gate cut This is a phenomenon where the gate connecting the formed

Quality engineering plastics are these 6 points? Engineering plastics (engineering-plastics) - refers to a class of high-performance polymer materials that can be used as structural

G-moulding is a mould brand of Grandshine Group,a professional mould manufacturer