How to improve the working life of plastic machine screw?

How to improve the working life of plastic machine screw barrel?

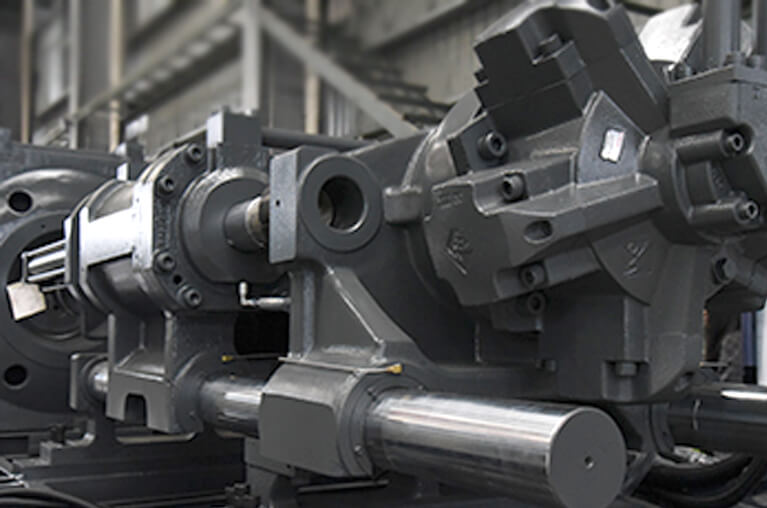

The injection molding screw is working under high temperature, high pressure, high mechanical torque and high friction for a long time. The first few factors are required by the process conditions, while wear and tear caused by friction is unavoidable.

Generally, screws are surface nitrides to improve surface hardness, i.e., to improve wear resistance. However, if the causes of wear are ignored and no attempt is made to minimize the wear, the working life of the screw will be greatly reduced.

The following explains the causes of screw wear and ways to reduce wear

1、each plastic, there is an ideal plasticized processing temperature range, should control the barrel processing temperature, so that it is close to this temperature range. Granular plastic from the hopper into the barrel

the first will reach the filling section, in the filling section will inevitably appear dry friction, when these plastics are underheated, uneven melting, it is easy to cause the inner wall of the barrel and screw surface wear increases. Similarly, in the compression section and the homogenization section, if the molten state of the plastic is disordered and uneven, it will also cause increased wear.

2、the speed should be properly adjusted. As some plastics are reinforced with reinforcing agents, such as glass fiber, minerals or other fillers. These substances often have much greater abrasive force on the metal material than the molten plastic.

In the injection molding of these plastics, if the high speed into the plastic, it will increase the shear force on the plastic at the same time, will also make the reinforcement correspondingly more torn fibers, torn fibers contain sharp ends, so that the abrasive force is greatly increased. Inorganic minerals in the metal surface at high speed glide, its scraping effect is not small. So the speed should not be adjusted too high.

3、to check and remove the debris in the plastic. In general, the original purchase of fresh plastic and there is no debris, but after transport, weighing, drying, color mixing, especially the addition of recycled back to the material, it is possible to mix debris.

Small as metal scraps, large as heating ring nuts paper clips, and even bunches of warehouse keys, mixed into the barrel have happened, which damage to the screw is self-evident (the barrel will also be damaged at the same time), so we must install a magnet frame, strict management and monitoring of feeding.

4、the water contained in the plastic, the wear and tear on the surface of the screw has a certain impact. If the plastic in the injection molding before not all the water excluded, residual water into the screw compression section, it will form before the melt mixed in the melt injection molding machine features and requirements are optional: section up to the head of the screw, these "steam particles", in the injection process unloading pressure expansion, such as a microscopic impurities hard particles, the wall abrasive damage.

In addition, for some types of plastics, under high temperature and pressure, moisture may become a catalyst for plastic cracking and produce harmful impurities that can erode metal surfaces. Therefore, the drying work before plastic injection is not only directly related to the quality of the parts, but also affects the working life of the screw.

Injection molding machine screw type

The screw can be selected according to the function and requirements of the injection molding machine:

Commonly used are:

Reciprocating screw (three-stage screw) Divided into progressive, experimental, and general-purpose types.

Screws for the production of marble-like products.

Vented type injection molding machine screw.

Pre-plasticizing screw for injection molding machine.

Compounding screw.

1、conventional injection molding screw:

general injection molding machine with a standard medium diameter screw, with two high and low pressure conventional screw, can be applied to a wide range of general plastics and engineering plastics processing

this screw is also three-stage:

charging section, compression section, homogenization section, are considered injection molding machine pre-molding and injection molding process the working characteristics of the material to determine.

2、lengthening injection molding screw:

is a higher plasticizing capacity of each better mixing effect of general-purpose injection butterfly rod

compared with conventional screws are characterized by: a large ratio of length to diameter (20 ~ 25), metering section long (30%), metering section shallow groove (0.04 ~ 0.05D), compression is relatively large (0.11 ~ 012D), so it is conducive to plasticizing each temperature cooperation.

3、type of rigid PVC injection molding screw:

this screw is characterized by: a small aspect ratio, metering and conveying section is shorter, compression section is longer, i metering section of the screw groove is deeper, compression is smaller, suitable for rigid PVC and other thermally unstable plastics for injection molding, in order to reduce the strong shear effect and storage, to prevent overheating decomposition

this seat screw is suitable with - melt In order to reduce the strong shearing and storage, and to prevent overheating decomposition, this type of seat screw is suitable for "Z" type screw head with melt flow.

4、no metering section injection molding screw:

light metering injection molding screw, also known as "ZM'' screw, which is characterized by no metering section, only the filling section and transition section, so this is a two-stage screw, as no metering section can reduce melt superheat

increase the plasticizing ability and mixing effect, so it is suitable for injection molding ABS and other non-crystalline materials to prevent shear overheating.

Such as used to process flame retardant impact-resistant polyethylene, polycarbonate, filled polyethylene, polyethylene, and filled nylon, etc., no metering section screw length to diameter ratio is generally 20, the length of the filling section and the transition section of 50% each, the recommended depth of each section screw groove.

5、separate injection molding screw:

(BM screw) separate injection molding screw to call the "BM" screw, has been widely used in injection molding, the main type of screw is characterized by the melt section (transition section, compression section) to increase a water sub-thread, the main thread groove into two parts

when the screw rotates the main thread scraping down the molten film from the screw prongs and the barrel of the gap into the sub-thread groove, so that the solid bed and the melt pool separate.

When the screw rotates, the molten film scraped by the main thread flows into the groove of the secondary thread from the gap between the screw prongs and the barrel, so that the solid bed is separated from the molten pool, thus maintaining good contact between the fixed body bed and the inner wall of the barrel, which facilitates transportation and heat transfer.

wavy screw has a "single wave" and "double wave", single-wave screw is characterized by the bottom diameter of adjacent grooves are equal, but is eccentric, and eccentric distance equal, and symmetrical open screw axis.

Because the depth of the screw groove along the axial direction is wavy periodic change, so the pre-molding material is subject to strong extrusion and strong shear, absorbing a lot of mechanical energy and energy conversion; injection should be vinyl chloride and other heat-sensitive materials, can reduce the degradation effect.

7、mixing type injection molding screw:

mixing type injection molding screw is characterized by the location of the mixing element in the metering section. Based on the analysis of the ordinary screw shows that; in the transition section, the polymer initial melting, in the rear edge of the thread also formed a molten film, so the entire homogeneous bed is actually surrounded by molten film, reducing the efficiency of melting, so in the transition zone

still to emphasize the role of stable melting and conveying appropriate, after the material through the transition section all, melting, barrier-type mixing elements ( straight groove mixing elements to also known as Maddook elements ) Other barrier type kneading elements, (diverted kneading elements also known as DIS-shaped kneading elements)

combination screw is mostly used in the screw metering section of the heart pumping, according to the different nature of the material to install different functions of the mixing components group, mixing components made into the form of a key, and connected with the key and the heart, the end face of the set should be precise with, to prevent the melt into.

Thank you for watching, we are a professional manufacturer, please contact us for more information!