I、Terminology explanation

Cracks are formed on the surface of the molded product and are called cracks.

1、The residual stress is too high. In mold design and production, direct gates with minimum pressure loss and can withstand higher injection pressure can be used. Positive gates can be changed to multiple needle-shaped point gates or side gates and the diameter of gates can be reduced. When designing side gates, a tab type gate can be used which can remove the broken part after molding.

In terms of process operation, reducing the residual stress by lowering the injection pressure is the easiest way, because the injection pressure is proportional to the residual stress. The temperature of the barrel and mold should be increased appropriately, the temperature of the melt and mold should be reduced, and the cooling time and speed of the mold embryo should be controlled so that the oriented molecule even has a longer recovery time.

2、External forces cause residual stress concentrations. In general, this kind of failure always occurs around the ejector rod. After this kind of failure, should be carefully checked and calibrated ejector device, the top bar should be set in the largest part of the mold release resistance, such as the tab, reinforcement, etc.. If the number of ejector bars set is not possible to expand due to the condition of pushing the roof area, the method of small area with multiple ejector bars can be used. If the mold cavity release slope is not enough, the surface of the plastic parts will also appear scratched to form a crease pattern.

3、There is a difference between the coefficient of thermal expansion of the molding material and the metal insert. For the metal insert should be preheated, especially when the cracks on the surface of the plastic parts occur at the beginning of the machine, most of them are caused by the low temperature of the insert.

In addition, in the choice of insert material, should try to use the coefficient of linear expansion close to the resin characteristics of the material. In the selection of molding materials, should also be used as far as possible, high molecular weight resin, if it is necessary to use low molecular weight molding materials, the thickness of the plastic around the insert should be designed thicker.

4、Improper selection of raw materials or impure. Practice shows that low-viscosity sparse resin is not easy to produce cracks. Therefore, in the production process, the appropriate molding raw materials should be selected with the specific situation.

During the operation, special attention should be paid not to mix polyethylene and polypropylene and other resins together, which can easily produce cracks. In the molding process, the release agent is also a foreign substance for the melt, such as improper dosage will also cause cracks, should try to reduce its dosage.

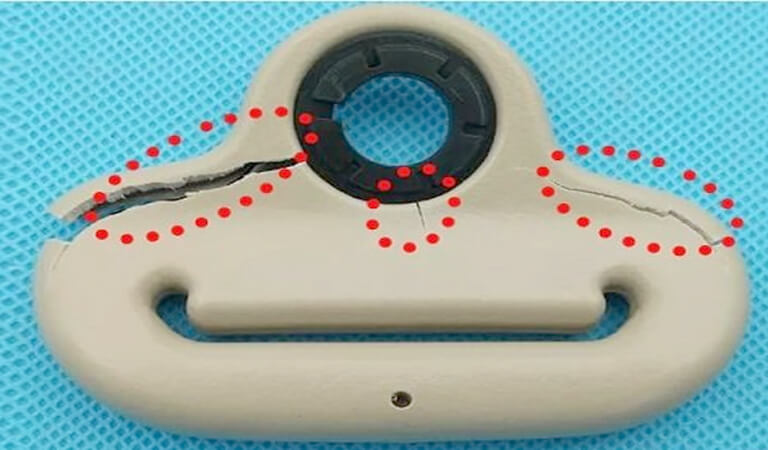

5、Poor structural design of plastic parts. The sharp corners and notches in the structure of the plastic part are most likely to produce stress concentration, resulting in cracks and ruptures on the surface of the plastic part. Therefore, the outer and inner corners of the structure of the plastic part should be made of the largest possible radius into an arc. The test shows that the best excessive arc radius is the ratio of arc radius and wall thickness at the corner is 1:1.7.

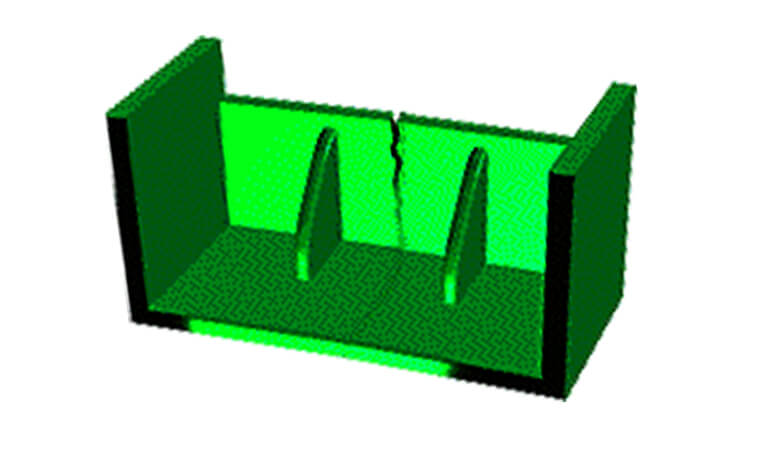

6、Cracks on the mold are reflected on the surface of the molded part. In the injection molding process, due to the repeated action of injection pressure on the mold, fatigue cracks will be generated in the cavity with sharp edges, especially in the vicinity of the cooling hole.

When the crack on the surface of the mold cavity is mirrored on the surface of the plastic part, the crack on the surface of the plastic part always appears continuously in the same shape on the same part. When such cracks appear, the surface of the cavity corresponding to the crack should be checked immediately for the same cracks. If the cracks are caused by the re-imaging effect, the mold should be repaired by mechanical processing.

Thanks for watching the full article! Click here to learn more about injection molding, please!